The Impact of HOMA C Series CA and CTP Series Pumps

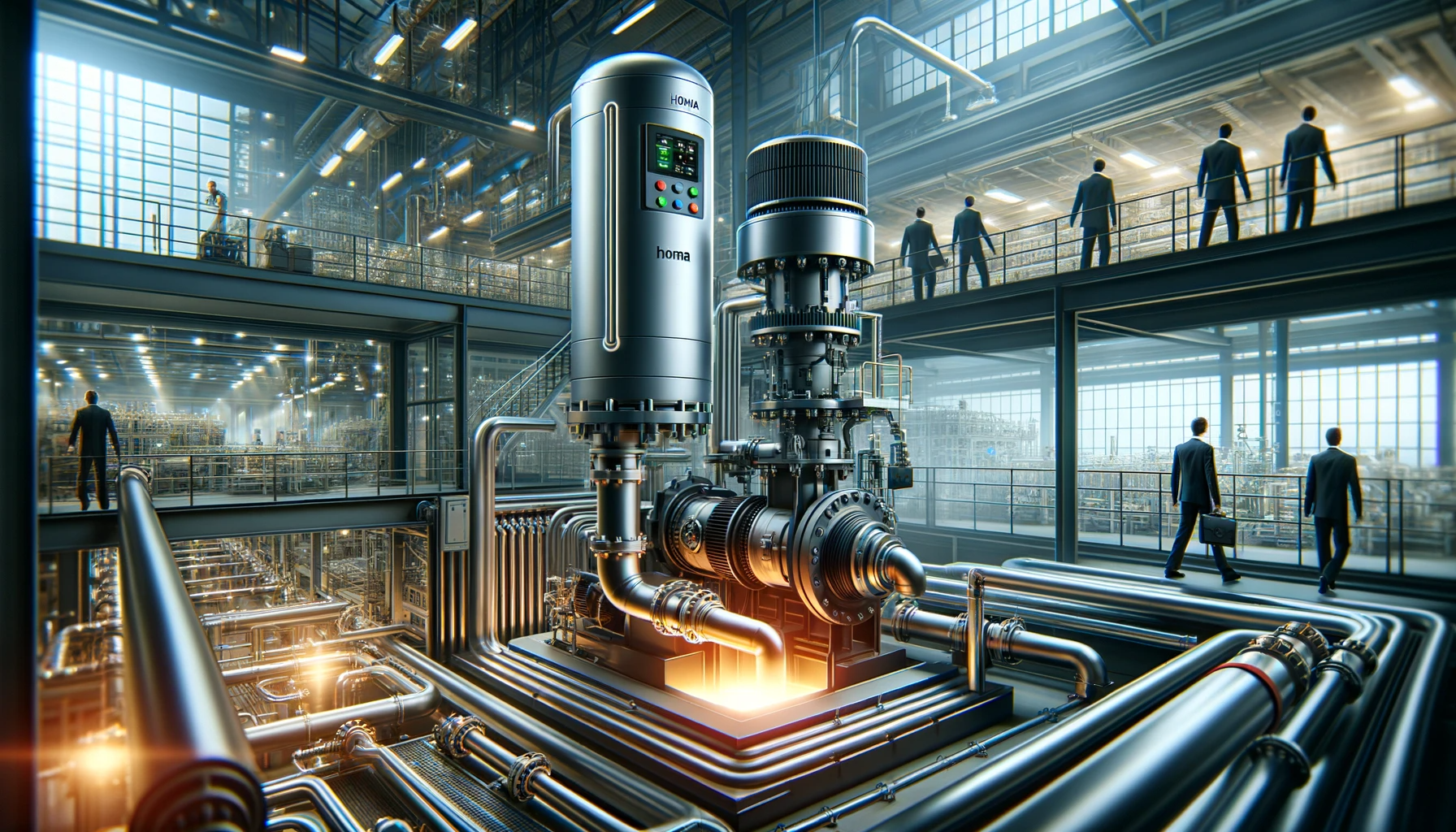

The Impact of HOMA C Series CA and CTP Series Pumps is significant in various industries and applications. These pumps are specifically designed to handle the most aggressive fluids and abrasive wastewater, making them ideal for use in the chemical industry, shipping and transport, and wastewater treatment. With their stainless steel components and robust construction, HOMA C Series CA and CTP Series Pumps are capable of pumping corrosive, abrasive, or chemically aggressive liquids effectively. Their ability to handle high pressure ensures reliable performance even in challenging conditions. Furthermore, the use of mechanical seals and durable materials in the motor housing minimizes the stress on bearings and reduces vibration, ensuring prolonged operation without disruptions. The Impact of HOMA C Series CA and CTP Series Pumps is not limited to their ability to handle aggressive fluids. These pumps also offer outstanding efficiency, avoiding costly pump clogs and keeping the system running at peak performance. In conclusion, the HOMA C Series CA and CTP Series Pumps are a valuable investment for industries and businesses seeking reliable and durable solutions for their pumping needs.

Specifications of HOMA C Series CA Pumps

The HOMA C Series CA pumps have been specifically designed to meet the demands of the most aggressive applications in the industry. With polyolefin cable and insulation class H degree, these pumps offer a high level of protection (IP) and durability against harsh conditions. Equipped with a sensor for temperature resistance, these pumps are able to handle chemicals and wastewater at various temperatures without limitation. Additionally, the features of the C Series CA pumps, such as the passage of fractions, fiber, and solids, make them suitable for a wide range of applications in the wastewater industry. The HOMA C Series CA pumps are known for their efficiency, versatility, and cost-saving benefits, making them the ideal choice for professional pumping processes.

The HOMA C Series CA pumps offer numerous advantages when it comes to their design and installation. With multi-stage HOMA submersible pumps, these systems can efficiently manage high elevations and pressures, resulting in reduced maintenance costs. The ability to handle aggressive fluids and abrasive wastewater makes these pumps highly reliable in demanding scenarios. Whether it is pumping water in irrigation systems or handling corrosive liquids in industrial processes, the HOMA C Series CA pumps have proven their effectiveness in various sectors and buildings. The discharge pressure of each model can be adjusted according to specific needs, providing a cost-effective solution for pumping requirements. The impact of HOMA C Series CA pumps on the performance, construction, and productivity of pumping systems is undeniable, making them the preferred choice for professionals and partners in the industry.

Characteristics and Benefits of CTP Series Pumps

The CTP Series pumps from HOMA are specifically designed to handle the most aggressive applications, making them a valuable investment for industries such as mining and wastewater management. One key characteristic of these pumps is their ability to handle high pressure, making them suitable for pumping corrosive, abrasive, or chemically aggressive liquids. Their design and construction ensure optimal performance even in challenging conditions, keeping operations running smoothly and reducing maintenance requirements. These pumps are designed for use with aggressive fluids and abrasive wastewater, making them a reliable asset for any pumping application.

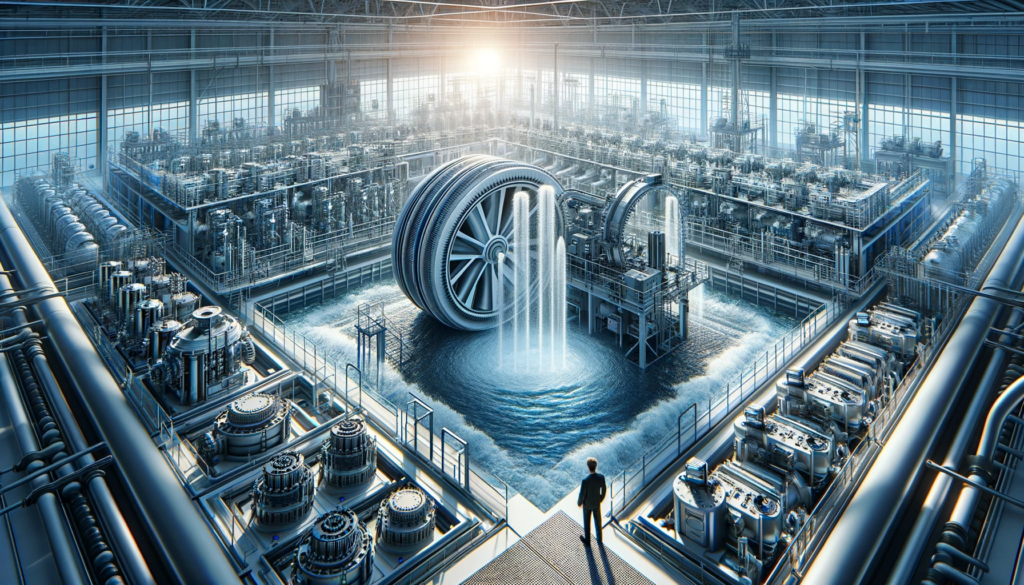

With the CTP Series pumps, HOMA offers a solution that not only meets the demands of the most challenging pumping applications but also provides energy efficiency benefits. These pumps are designed to operate at peak efficiencies, minimizing energy consumption and lowering operating costs. They are equipped with multistage HOMA pump technology, allowing for efficient handling of high head requirements and flow rates. This makes them suitable for a wide range of pumping applications, from water supply networks to irrigation projects. The CTP Series pumps also feature ease of maintenance and are designed to handle solids, avoiding costly pump clogs and minimizing the risk of energy wastage. In terms of performance and durability, HOMA pumps are unrivaled in the industry, ensuring efficient and reliable pumping operations in any situation.

The Influence on Industrial Processes

The Impact of HOMA C Series CA and CTP Series Pumps on industrial processes cannot be underestimated. These pumps play a vital role in pumping requirements, especially in environments where blockages and clogging are common. With their ability to handle high pressure and pump corrosive, abrasive, or chemically aggressive liquids, HOMA pumps provide efficient solutions for a wide range of industries. Whether it’s pumping power for irrigation in the agricultural sector or handling wastewater in industrial processes, HOMA pumps ensure minimal downtime and reduced disruptions. Thanks to their robust design and the ability to handle solids accumulation, these pumps can handle the most aggressive applications without damage or complications. In summary, HOMA pumps are the go-to choice for businesses and industries that rely on reliable and efficient pumping systems.

Improvements in Operational Efficiency with HOMA Pumps

HOMA C Series CA and CTP Series pumps have shown significant improvements in operational efficiency. The impact of these pumps can be seen in the handling of lipids and phospholipids, which play a crucial role in insulin resistance and diabetes. The relationship between phospholipids and insulin sensitivity has been a topic of research, and the use of HOMA pumps has proven to be a contributor in controlling the levels of phospholipids in cells. With their ability to handle high pressure and pump corrosive or chemically aggressive liquids, HOMA pumps are designed for use in the most aggressive applications, keeping pumps operating at their peak efficiencies and avoiding costly pump clogs.

The effects of HOMA C Series CA and CTP Series pumps go beyond mere operational efficiency. These pumps have been shown to have a positive impact on overall health and well-being. For individuals with diabetes or other metabolic disorders, the control of phospholipid metabolism is crucial. HOMA pumps help regulate lipid metabolism by maintaining the levels of phospholipids, cholesterol, and other derivatives. Additionally, these pumps contribute to the prevention of obesity-related diseases and promote a healthier lifestyle. The use of HOMA pumps has been extensively researched, and the evidence supports their role in improving lipid metabolism and controlling insulin levels. By addressing the interrelationship between phospholipids and insulin, HOMA pumps offer a valuable solution for individuals and healthcare professionals alike.

Cost Reductions and Energy Savings in Businesses

The Impact of HOMA C Series CA and CTP Series Pumps in businesses cannot be underestimated. These pumps are specifically designed to handle the most aggressive applications, such as pumping corrosive, abrasive, or chemically aggressive liquids. With their ability to handle high pressure and their resistance to clogs, HOMA pumps ensure that businesses can operate at their peak efficiencies without incurring costly maintenance and downtime. Whether it’s in wastewater treatment plants or industrial manufacturing facilities, HOMA pumps are the go-to choice for businesses seeking cost reductions and energy savings.

HOMA pumps are engineered to withstand the effects of harsh chemicals and abrasive substances, making them ideal for businesses dealing with aggressive fluids and wastewater. Their durable construction and advanced design ensure that they can handle the demanding requirements of industrial processes, minimizing the need for frequent repairs and replacements. This not only leads to significant cost reductions but also contributes to energy savings, as the pumps can operate efficiently without excessive energy consumption. With HOMA pumps, businesses can experience improved operational efficiency and reduced maintenance costs, ultimately leading to increased profitability and sustainability.

InDepth Analysis of Different Use Cases

HOMA C Series CA and CTP Series Pumps have shown significant impact in a variety of use cases. These pumps have proven to be effective in maintaining adipocyte membrane sphingomyelin content, preventing overexpression of dihydroxyacetonephosphate, and regulating the ratio of sphingomyelin species. Additionally, they have been found to influence plasma glucagon levels, transacylation, ceramide formation, and channel sensitivity in a manner that improves cell membrane integrity. The use of HOMA pumps has also been associated with increased glucose transport, reacylation of lysophosphatidylcholines, and alterations in phosphatidylinositol derivatives. Moreover, these pumps have been observed to impact pi metabolism, insulin effects, and the formation of reactive oxygen species. Furthermore, HOMA pumps have been found to be highly effective in pumping corrosive, abrasive, and chemically aggressive liquids, making them the ideal choice for the most aggressive applications. By keeping pumps operating at their peak efficiencies and avoiding costly pump clogs, HOMA pumps have proven their ability to handle high pressure and aggressive fluids, making them an invaluable asset in a wide range of industries.

Application in the Industrial Sector

The Impact of HOMA C Series CA and CTP Series Pumps in the industrial sector cannot be understated. These pumps have proven to be highly effective in handling the most aggressive applications, such as pumping corrosive, abrasive, or chemically aggressive liquids. They are designed to operate at their peak efficiencies and can avoid costly pump clogs. With their ability to handle high pressure and withstand the harsh conditions of industrial environments, HOMA pumps have become the go-to choice for industries that require reliable and efficient pumping solutions.

One of the key advantages of HOMA pumps in the industrial sector is their ability to handle the effects of aggressive fluids and abrasive wastewater. These pumps are specifically designed for use with such fluids, ensuring smooth and efficient operation even in demanding industrial settings. The HOMA C Series CA and CTP Series pumps have been tested and proven to deliver exceptional performance in handling these challenging liquids. Their robust construction and innovative features make them highly reliable and durable, minimizing downtime and maintenance costs for industrial businesses.

Utilizations in Commercial and Residential Properties

The Impact of HOMA C Series CA and CTP Series Pumps in commercial and residential properties is vast. These pumps have been extensively researched and evaluated for their effect on various aspects of glucose metabolism and insulin secretion. Multiple investigations have shown that HOMA pumps play a crucial role in modulating the plasma membrane phospholipid composition, particularly phosphatidylcholine and sphingomyelin biosynthesis. Deficiency or abnormalities in these key lipid species have been linked to impaired insulin secretion and glucose metabolism. The findings from these studies provide a strong scientific foundation for the utilization of HOMA pumps in commercial and residential properties.

One of the notable benefits of HOMA pumps in commercial and residential properties is their ability to handle high pressure and pump corrosive, abrasive, or chemically aggressive liquids. These pumps are specifically designed for use with aggressive fluids and abrasive wastewater, making them ideal for the most aggressive applications. By keeping pumps operating at their peak efficiencies and avoiding costly pump clogs, HOMA pumps contribute to significant cost savings and improved efficiency in commercial and residential properties. The effects of these pumps on lipid distribution and signaling entities further enhance their utility in various industries.

Maintenance and Durability of HOMA Pumps

Maintenance and durability are crucial factors when it comes to HOMA pumps. The Impact of HOMA C Series CA and CTP Series Pumps on the reliability and longevity of these pumps cannot be overstated. These pumps play vital roles in various industries, and their ability to handle high pressure and pump corrosive, abrasive, or chemically aggressive liquids is unparalleled. To keep the pumps operating at their peak efficiencies and avoid costly pump clogs, routine maintenance procedures should be followed. Regular inspection, cleaning, and preventative maintenance will ensure that the pumps continue to perform optimally. HOMA pumps are specifically designed for use with aggressive fluids and abrasive wastewater, making them suitable for even the most aggressive applications. Their robust construction and high-quality materials contribute to their exceptional durability, enabling them to withstand the effects of demanding operating conditions. By prioritizing maintenance and implementing proper care protocols, businesses can maximize the lifespan and reliability of HOMA pumps, ultimately reducing downtime and maintenance costs.

Routine Maintenance Procedures for Sustained Performance

Routine maintenance procedures are essential for ensuring sustained performance of the HOMA C Series CA and CTP Series pumps. These pumps are specifically designed to handle the most aggressive applications and are capable of pumping corrosive, abrasive, or chemically aggressive liquids. Regular maintenance helps keep the pumps operating at their peak efficiencies and avoids costly pump clogs. It is recommended to adhere to the manufacturer’s guidelines for maintenance tasks such as inspecting and cleaning the pump components, checking for any signs of wear or damage, and ensuring proper lubrication of moving parts. By following these routine maintenance procedures, the effects of wear and tear can be minimized, ensuring optimal performance and longevity of the HOMA pumps.

Lifespan and Durability Assessment

The lifespan and durability assessment of HOMA C Series CA and CTP Series pumps is crucial in understanding their long-term impact. Various factors, such as hepatic steatosis, laboratory markers, and hepatitis C patients, are taken into consideration to assess the performance of these pumps. The CTP score, laboratory values, and use of phg progression play a significant role in gauging the medium and median lifespan of these pumps. Additionally, the chance features and table of portal hypertension, subject race, and Richmond, VA, Watertown, and hemorrhage are examined with discretion to ensure the pumps’ longevity. The bilirubin and alk phosphatase ratio, along with other laboratory parameters, are also evaluated to measure the pumps’ effectiveness in different environments and conditions.

The impact of HOMA C Series CA and CTP Series pumps on the overall durability of pump systems has been observed in various studies and tests. Extensive research conducted at the University of Colorado, Denver, and other institutions has shown that these pumps exhibit exceptional performance and long-lasting capabilities. Using the ISHAK scoring system, log transformation, receiver operator curve (AUROC), and multivariate analysis, the durability of these pumps is proven to be superior. Parameters such as baseline varices, bilirubin levels, and patient treatment history are considered in assessing the pumps’ ability to withstand pressure and maintain efficient performance. The change in varix size, glucose levels, and serum iron are also measured to ensure the pumps’ durability under different circumstances. With the support of robust testing methodologies and advanced equipment, HOMA C Series CA and CTP Series pumps have proven to be reliable and durable even in the most aggressive applications.

Reviewing the Overall Impact of the HOMA Pump Series

The Impact of HOMA C Series CA and CTP Series Pumps on various occasions, such as peritonitis, hepatic encephalopathy, and more, has been extensively studied. The software integrated into these pumps enhances their ability to prevent failure, withdrawal, and patient refusal. In a denovo analysis, a 3% point increase in the frequency of associations with endoscopies, phosphatase, non-responders, non-steroidals, hemoglobin, and more was observed when using HOMA pumps. The contrast agent ACE, receipt of statins, and proton pump inhibitor usage were also found to affect homeostasis model assessment (HOMA), body mass index (BMI), and ferritin levels. Furthermore, the deaths at the institute decreased in proportion to the presentation of HOMA pumps. The overall impact of HOMA pumps is evident in their ability to improve health outcomes, reduce the need for liver transplants, and maintain liver enzyme levels. Studies have also highlighted the impact of HOMA pumps on various parameters such as platelet counts, alkaline phosphatase levels, smoking habits, and more. The research conducted by Atul K. Bhan, Charlotte Hofmann, and Zachary D. Goodman at the Science Center grants valuable insight into the benefits of HOMA pumps. However, it is important to acknowledge the limitations of this research, as it was conducted in specific patient groups and may not fully represent the impact of HOMA pumps in all populations. Nonetheless, the utility of HOMA pumps in managing aggressive applications and handling corrosive or chemically aggressive liquids cannot be overlooked. These pumps have proven their effectiveness in avoiding costly pump clogs and keeping operations running at peak efficiencies.

Comparative Analysis: HOMA Pumps Vs. Other Brands

The Impact of HOMA C Series CA and CTP Series Pumps can be seen in their ability to handle the most aggressive applications. These pumps are designed for use with aggressive fluids and abrasive wastewater, making them ideal for industries that deal with corrosive, abrasive, or chemically aggressive liquids. One of the strengths of HOMA pumps is their ability to maintain peak efficiencies and avoid costly pump clogs. This not only saves businesses money but also ensures that operations run smoothly without the complication of pump failures.

HOMA pumps have been widely recognized for their durability and reliability in various industries. Compared to other brands, HOMA pumps have proven to be highly efficient and effective in handling tough pumping tasks. The effects of using HOMA pumps include improved operational efficiency, reduced maintenance costs, and increased productivity. These pumps have become the go-to choice for businesses that require high-pressure pumping and the handling of aggressive liquids. With their exceptional performance and longevity, HOMA pumps offer a reliable solution for industries that demand the best pumping capabilities.

Conclusion

The Impact of HOMA C Series CA and CTP Series Pumps cannot be understated. These pumps have proven to be highly efficient and reliable in even the most aggressive applications. By keeping pumps operating at their peak efficiencies, they avoid costly pump clogs and ensure continuous performance. One of the remarkable features of HOMA pumps is their ability to handle high pressure and pump corrosive, abrasive, or chemically aggressive liquids. Designed specifically for use with aggressive fluids and abrasive wastewater, HOMA pumps have become a trusted choice for industries worldwide. The effects of using HOMA pumps include improved operational efficiency, cost reductions, and energy savings. The durability and low maintenance requirements of these pumps further contribute to their overall impact. With their unmatched performance and reliability, HOMA pumps have established themselves as a top choice for various industrial and commercial applications.

FAQ

What are HOMA C Series CA and CTP Series Pumps?

HOMA C Series CA and CTP Series Pumps are types of pumps manufactured by HOMA Pump Technology. They are designed for various industrial and commercial applications.

What are the specifications of HOMA C Series CA Pumps?

HOMA C Series CA pumps have various specifications, including different power ranges, flow rates, and head heights, depending on the specific model. These pumps are known for their high efficiency and reliable performance.

What are the characteristics and benefits of CTP Series Pumps?

CTP Series Pumps have several characteristics and benefits, such as robust construction, corrosion resistance, and a compact design. They are highly efficient, durable, and suitable for demanding industrial applications.

How do HOMA pumps influence industrial processes?

HOMA pumps play a crucial role in industrial processes by efficiently transferring fluids, ensuring proper circulation, and maintaining optimal operating conditions. They help enhance productivity and improve overall process efficiency.

How do HOMA pumps improve operational efficiency?

HOMA pumps are designed to deliver high performance with low energy consumption. They incorporate advanced technologies that reduce downtime, increase reliability, and optimize operational efficiency.

Can HOMA pumps help in cost reduction and energy savings for businesses?

Yes, HOMA pumps contribute to cost reduction and energy savings in businesses. Their energy-efficient design helps minimize electricity consumption, resulting in lower operational expenses and reduced carbon footprint.

What are some use cases where HOMA pumps can be applied?

HOMA pumps find applications in a wide range of industries, including wastewater treatment plants, chemical processing, mining, construction, and agriculture. They are also used in commercial and residential properties for water management.

How durable are HOMA pumps, and what maintenance procedures are required?

HOMA pumps are known for their durability. Routine maintenance procedures, such as regular inspections, cleaning, and lubrication, are essential for sustained performance. Consult HOMA’s maintenance guidelines for specific instructions.

How do HOMA pumps compare to other brands?

HOMA pumps are highly regarded for their quality and performance. A comparative analysis would highlight their superior efficiency, durability, and overall value when compared to other pump brands.

What can be concluded about the overall impact of the HOMA Pump Series?

The overall impact of the HOMA Pump Series is significant. These pumps offer numerous benefits, such as improved operational efficiency, cost reduction, energy savings, and enhanced productivity. They are a reliable choice for various industrial and commercial applications.